Категории

Набор инструментов для чекеринга, N3, 90°/18линий, 10 предметов

Описание

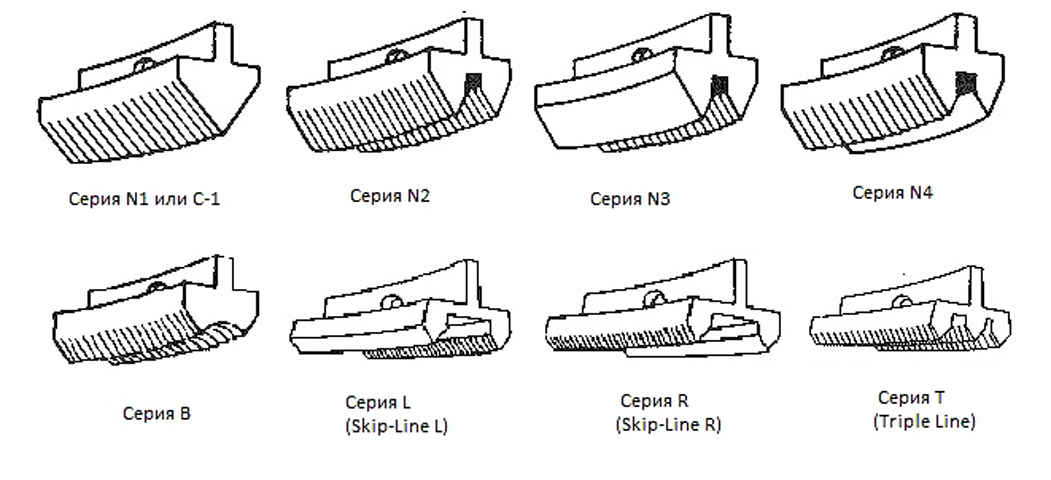

Набор инструментов для чекеринга, N3, 90°/18линий, 10 предметов. Резцы для чекеринга ПЕТРОГРАДЪ. Чекеринг - вид резьбы по дереву и украшения рукоятей, прикладов и оружейных лож. Инструменты для чекеринга под маркой Петроградъ представляет российская компания RUBANKOV. Резцы для чекеринга нашей марки выполнены на основе опыта, полученного при эксплуатации резов известных мировых производителей. Модельный ряд содержит все основные резцы размером от 16 до 32 линий на дюйм с углами заточки 60° и 90°. Ко всем резцам можно докупить запасные режущие насадки и шаблон.

Более подробную информацию вы можете прочитать у нас на сайте в статье: «Резцы для нанесения чекеринга, типы и виды».

Внимание! Сейчас резцы для чекеринга приходят со вклеенной насадкой (ранее насадка крепилась на медный штифт). Резцы могут быть с насадками обоих типов. Вклеенные насадки легко меняются. Для этого достаточно разогреть место склейки или воспользоваться жидкостью для удаления цианакрилатного клея.

Набор включает 10 резцов

Резец для чекеринга S-1, 90° (одна РК)

Резец для чекеринга штихель, 90°

Резец для чекеринга L- 9, 90° (РК - слева, направитель - справа, широкий промежуток)

Резец для чекеринга N2-18, 90° (две РК)

Резец для чекеринга B-2 (две РК, промежуток - с зубцами)

Резец для чекеринга N3-18, 90° (направитель - справа, РК - слева)

Резец для чекеринга R- 9, 90° (направитель - слева, РК - справа, широкий промежуток)

Резец для чекеринга N4-18, 90° (РК - справа, направитель - слева)

Разметчик для резьбы на прикладах

Резец для чекеринга C-1, 90° (одна РК)

Шаблон для чекеринга

Сумка-скрутка тканевая, ПЕТРОГРАДЪ, модель 1, для резчицких инструментов, 12 карманов

Вы уверены?

Поделиться / Сохранить себе ссылку: