Категории

Что такое Чекеринг

Чекеринг это особое старинное искусство функционального декорирования прикладов иложементов ружей. В простом понимании это группы параллельных и перпендикулярных линий (канавок) нанесенных под строго заданным углом, в конечном итоге данный тип нанесения формирует ромбический рисунок. В некоторой английской литературе checkering пишется, как chequering.

Основная функция чекеринга придание хвату стрелка большее сцепление, особенно в плохую погоду, когда приклад скользкий и грязный, или когда ладони стрелка вспотели от длительной сессии стрельбы.

Вторая, и вероятно наиболее важная функция чекеринга, это конечно же украшение ружья или любого другого предмета. Чекеринг эффектно подчеркивает формы и грацию линий приклада. Для ясности, чекеринг не является необходимым для большинства ружей и рукоятей ножей, но от этого не меньше хочется им их украсить.

В текущем своем виде чекеринг появился, где-то лет 150 назад. Однако это не значит, что до этих дней не было чекеринга как такового, но узоры и способы нанечения рисунка были отличными от современных.

Чекерение ложемента может быть произведено различными методами и с различными типами узоров. Наиболее известная техника и узор - островерхий (pointed), данный узор выглядит как продолговатый ромбики или даже брильянты с острым навершием. Существуют так же и другие типы рисунков: плоский (flat-top) и полуплоский (semi flat-top). Другие разновидности это ответвления основных типов, например Французский чекеринг, так же известный, как чекеринг с пропуском линий, порой его так же называют Шотландским чекерингом. В этой технике нанесения линии просто пропускаются с заданным интервалом, что создает квадратный узор очень схожий с орнаментом Тартан (шотладка). Тартан это клетчатый узор из коризонтальных и вертикальных линий.

Островерхий чекеринг

Это наиболее распространенный тип чекеринга. При нанесении этого узора, канавки нарезаются под углом 90 градусов (порой при 60). Получающиеся ромбики - острые с высоко приподнятым острием, они очень похожи на брильянт. Этот тип чекеринга дает прекрасный хват и практически не засоряется и легко самоочищается благодаря своему открытому углу. Этот тип чекеринга может быть слишком острым и будет врезаться в руку при долгий сессиях стрельбы или на прикладах ружей с сильной отдачей.

Так же в месте нанесения чекеринга, богатая текстура дерева может быть не читаема, но это зависит от качества исполнения работы и от самой древесины конечно же.

Инструменты для нанесения островерхого рисунка, вы можете найти в нашем каталоге. Смотрите на маркировку угла.

Плосковерхий чекеринг ( Английский тип)

Рисунок этого типа не формирует острых наверший, поэтому он просто плоский. Канавки этого рисунка достаточно глубокие и с параллельными стенками. Этот тип чекернга часто можно встретить на старинных английских ружьях. Главный недостаток этого узора, это то, что канавки легко заполняются грязью и делают их бесполезными для хорошего хвата.

С другой стороны, этот вариант чекеринга не разрушает природную красоту дерева и он более комфортабельный для ружей с сильной отдачей и для длительных сессий стрельбы.

Плосковерхий чекеринг, может быть легко переделан в островерхий, путем повторной прорезки линий, но уже резцом с угловой насадкой. Но при этом рисунок потеряет свои английские корни и может испортить видимую красоту текстуры дерева.

На сегодня компания Петроградъ не производит резцы для нанесения плосковерхих узоров.

Полуплоский тип чекеринга

Если мы будем резать канавки с углом в 60 градусов, то получится нечто среднее между островерхим и плосковерхим чекерингом. Этот тип канавок так же не очень глубок и не обладает острыми вершинами. Полуплоский чекеринг зачастую просто иметирует плоский Английский чекеринг. Сам по себе этот тип канавок, пытается устранить недостатки плосковерхого чекеринга, пытаясь сделать его менее восприичивым к забиванию грязью.

Этот узор чаще всего заполняющий, это можно понять по внешней границе, которая не параллельна резу канавок чекеринга.

Типы узоров чекеринга

Все вместе, линии чекеринга формируют узор. Существует несколько основных узоров. Чаще всего границы чекернга определяются границей орнамента или самого объекта. Бывает правда, что границ нет как токовых. В этом случае граница формируется крайней линией чекеринга или очень тонкой прорезной линией. Эта техника называется бесконечный чекеринг.

Заполняющий узор

При этом типе узора, сначала вырезается рамка, а уже затем пространство внутри заполняется узором. Этот узор чаще всего выглядит как угловой узор, однако разницу видно невооруженным взглядом, внешняя линия (рамка) не параллельна линиям чекеринга.

Ниже можно посмотреть примеры заполняющего полуплоского чекеринга, на рисунке слева. На картинке справа изображен инструмент для нанесения разметочных линий параллельно форме рукояти или форме ложемента.

Необычный чекеринг

Некоторые американские мастера достигли небывалых высот в этом типе искусства, по этому порой можно встретить очень необычные и невероятно сложные узоры. Чаще всего подобные узоры можно встретить на самых дорогих европейских ружьях.

На картинке можно видеть два узора, на нижнем изображен потрясающей красоты охотничье ружье Паркер с очень необычным волнообразным узором. Ружье было урашено в те дни, когда рабочая сила была относительно дешовой, а у людей хватало терпения тратить бесчисленные часы на безупречное выполнение очень сложных узоров.

К слову в Европе отношение к чекерингу намного более практичное. Простые узоры с несложным углом были нормой даже для самых дорогих ружей. Позже под влиянием американских мастеров, европейцы так же стали более притезательно относится к дизайну и качеству исполнения чекеринга.

Угловой узор

Этот узор - настоящий вызов мастера, всё дело в том , что граница узора формируется самим чекерингом. Самое же главное это то что сам чекеринг должен идти абсолютно параллельно границе узора. В следствии этого необходимо приложить не мало усердия для достижения данного эффекта, особенно это касается углов. Если угол реза соблюдается верно, то вершинки сформировавшихся ромбиков будут строго направлены относительно границы рисунка.

Этот тип чекеринга чаще встречается на ложементах более качественных и дорогих ружей. Обычно самые лучшие ложементы и ружья оформлены с помощью данной техники.

Для примера, на правой картинке изображен островерхий чекеринг , обратите внимание, что линии чекеринга строго параллельны границе чекеринга, что и делает его угловым узором.

Оборачивающий узор

Этот тип узора также относится чаще к заполняющему или угловому узору. Обернутый всего лишь обозначает, что чекеринг распространяется с одной стороны ложемента на другую, как бы опоясывая его.

На фото ниже можно увидеть пример оборачивающего островерхого чекеринга. На фото справа изображен набор инструментов для качественного выполнения чекеринга.

Чекеринг в процессе, как это делается

На фото слева можно увидеть, как чекеринг наносится на деревянную поверхность. Сначала наносится базовая линия, а затем нарезаются параллельные ей насечки.После нанесения линий, они будут углублены отдельным резцом. Более подробно можно посмотреть в видео ниже. В материале используются современные резцы для чекеринга от фабрики Петроградъ.

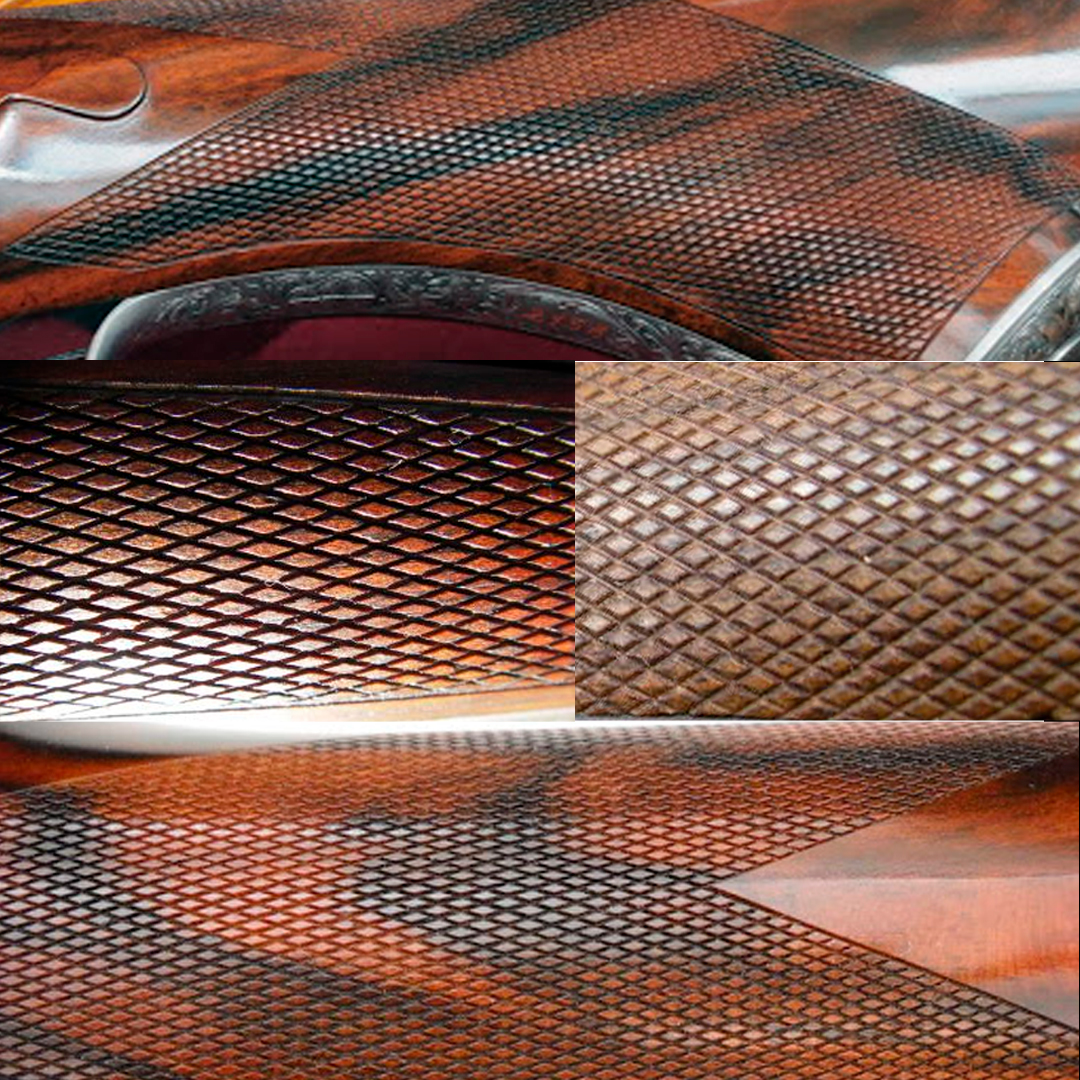

Чекеринг рыбьи чешуйки (чешуйчатый чекеринг)

Еще один необычный вид чекеринга - чешуйчатый чекеринг. Это абсолютно другая техника исполнения для которой необходимы другие специальные инструменты. По существу, это скорее резьба нежели чекеринг.

Этот тип чекеринга очень популярен в германоговорящих странах, но вы врятли встречали его на просторах Англии или Соединенных Штатов.

Это очень трудоемкий тип чекеринга, который так же требует повышенного внимания и аккуратности от мастера.

Рыбьи чешуйки придают рукояти очень хороший хват, они очень изящно смотрятся. Хотя по первости может быть очень непривычно и придется привыкать к ощущениям.

На этом все, спасибо за ваше внимание. С инструментами для чекеринга вы можете ознакомиться в нашем каталоге.